Calcium sulfate (or

calcium sulphate)

Chemical formula : CaSO4 (anhydrous form)

(Ca = 29.5 %, S = 23.5 %, O = 47 % )

Molar mass (M) = 136,14 g·mol-1

In the natural state, unrefined calcium sulfate is a translucent,

crystalline white rock.

Notes: heating the gypsum between 100 °C and 150 °C.,

partially dehydrates the mineral by driving about 75% of water

contained in its chemical structure. The temperature and time

required depends on the partial pressure of water. Temperatures of

170 °C are used in industrial calcination, but at these

temperatures the anhydrite is starting to form.

The reaction of partial dehydration is:

The partially dehydrated mineral is called calcium sulfate

hemihydrate or calcined gypsum ("plaster of

Paris") (CaSO4·nH2O), where n is in the range 0.5 to

0.8.

In contrast to most minerals, which when rehydrated simply form

liquid or semi-liquid pastes, or remain powdery, calcined gypsum has

an unusual property: when mixed with water at normal (ambient)

temperatures, it quickly reverts chemically to the preferred

dihydrate form, while physically "setting" to form a rigid and

relatively strong gypsum crystal lattice:

This reaction is exothermic and is responsible for the ease with

which gypsum can be cast into various shapes including sheets

(for drywall), sticks (for

blackboard chalk), and molds (to immobilize

broken bones, or for metal casting). Mixed with polymers, it

has been used as a bone repair cement. Small amounts of calcined

gypsum are added to earth to create strong structures directly from

cast earth, an alternative to adobe (which loses its

strength when wet). The conditions of dehydration can be

changed to adjust the porosity of the hemihydrate, resulting in the

so-called alpha and beta hemihydrates (which are more

or less chemically identical).

On heating to 180 °C, the nearly water-free form, called y-anhydrite (CaSO4·nH2O where n = 0 to 0.05) is produced. y-Anhydrite reacts slowly with water to return to the dihydrate state, a property exploited in some commercial desiccants. On heating above 250 °C, the completely anhydrous form called ß-anhydrite or "natural" anhydrite is formed.

Natural anhydrite does not react with water, even over geological

timescales, unless very finely ground.

Commercial production and recovery.

The main sources of calcium sulfate are naturally occurring

gypsum and anhydrite which occur at many locations worldwide as

evaporites. These may be extracted by open-cast quarrying or by deep

mining. World production of natural gypsum is around 127 million

tonnes per annum.[

In addition to natural sources, calcium sulfate is produced as a

by-product in a number of processes:

These precipitation processes tend to concentrate radioactive

elements in the calcium sulfate product. This is particularly the

case with the phosphate by-product, since phosphate rocks naturally

contain actinides.

Main properties :

|

Product > |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

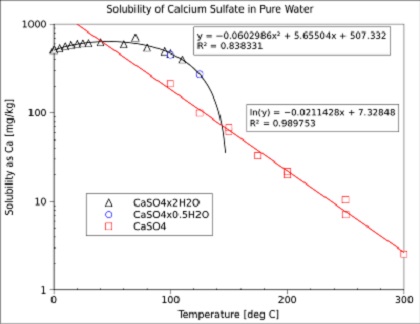

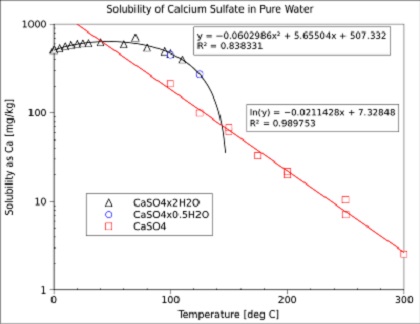

Calcium sulfate is an important component of fouling deposits in

industrial heat exchangers. This comes from its solubility decreases

with increasing temperature (see above Figure).

Note that the solubility of calcium sulfate in these steps is

approximately 10 times higher than which is calculated with the

solubility product (?).

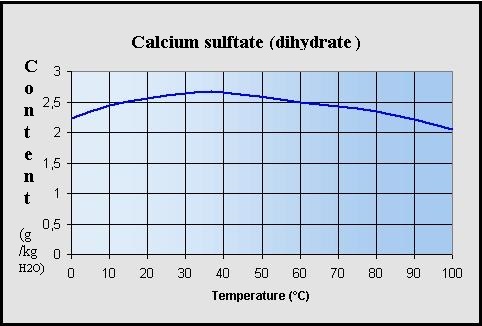

Maximum solubility of calcium sulfate dihydrate

[CaSO4.2H2O]

in soft water (g / kg H2O)

:

Uses.

In the form of y-anhydrite (the nearly anhydrous

form), it is used as a desiccant. It is also used as a

coagulant in products like tofu. In the natural state, unrefined

calcium sulfate is a translucent, crystalline white rock.

When sold as a color-indicating variant under the name Drierite, it

appears blue or pink due to impregnation with Cobalt(II) chloride,

which functions as a moisture indicator.

The hemihydrate (CaSO4·~0.5H2O) is better

known as plaster of Paris, while the dihydrate (CaSO4·2H2O)

occurs naturally as gypsum.

The anhydrous form occurs naturally as ß-anhydrite. Depending

on the method of calcination of calcium sulfate dihydrate, specific

hemihydrates are sometimes distinguished: alpha-hemihydrate and

beta-hemihydrate. They appear to differ only in crystal shape.

Alpha-hemihydrate crystals are more prismatic than beta-hemihydrate

crystals and, when mixed with water, form a much stronger and harder

superstructure.

In the treatment of water, it is mainly used for injection in the

form of water saturated solutions 1 to 2 g / L.

A formulation for water treatment.

Injection of 13,6 mg of CaSO4 in 1 liter of pure

water, calcium hardness (calcium) increases by 4 mg/L as Ca (or

1°F).

Storage.

Store in a cool, dry, well ventilated area away from heat and

moisture, and incompatible products.

Safety.

This product does not present a risk to health by inhalation,

ingestion or contact unless subjected to operations that can generate

the formation of particles in the air, and exposure to large amounts

of dust may cause irritation of skin, eyes, nose, throat, or upper

respiratory tract.

If in eyes, do not rub or scratch. To prevent mechanical irritation,

flush thoroughly with water for 15 minutes. If irritation persists,

consult a doctor.

Above 1450 ° C, decomposes to calcium oxide (CaO, or

"quicklime") and sulfur dioxide (SO2).

See also > International

Chemical Satefy Card 1215 (Canada) or

NIOSH

Pocket Guide to Chemical Hazards (USA)

Sources : personal and Wikipedia,

the free encyclopedia.

(use your browser)

(use your browser)