The maximum solubility in fresh water (20 °C) is 1 090 g / L.

Sodium hydroxide

(caustic soda, lye).

Chemical formula : NaOH

(Na = 57,48 %, O = 40 %, H = 2,52 %)

Molar mass = 39,9971 ± 0,0004 g·mol-1

Production.

Historically, sodium hydroxide was produced by treating sodium

carbonate with calcium hydroxide in a metathesis reaction. (Sodium

hydroxide is soluble while calcium carbonate is not.) This process

was called causticizing:

This process was superseded by the Solvay

process in the late 19th century, which was in turn supplanted by

the chloralkali process which we use today.

Sodium hydroxide is also produced by combining pure sodium metal with

water. The byproducts are hydrogen gas and heat, often resulting in a

flame, making this a common demonstration of the reactivity of alkali

metals in academic environments; however, it is not commercially

viable, as the isolation of sodium metal is typically performed by

reduction or electrolysis of sodium compounds including sodium

hydroxide.

Sodium hydroxide is industrially produced as a 50% solution by

variations of the electrolytic chloralkali process. Chlorine gas is

also produced in this process. Solid sodium hydroxide is obtained

from this solution by the evaporation of water.

Process being replaced (2020) by electrolysis membrane.

Also from sodium carbonate (caustication): this technique was that

previously used. It is still used in North America where natural

deposits of sodium carbonate. This is an addition of lime (Ca

[OH] 2) with sodium carbonate [Na2CO3]. The reaction

is written:

It is a white solid and highly caustic metallic base and alkali salt

which is available in pellets, flakes, granules, and as prepared

solutions at a number of different concentrations.

The dissolution in water of sodium hydroxide is known as lye.

Similar to the hydration of sulfuric acid, dissolution of solid

sodium hydroxide in water is a highly exothermic reaction in which a

large amount of heat is liberated, posing a threat to safety through

the possibility of splashing. The resulting solution is usually

colourless and odorless with slippery feeling upon contact in common

with other alkalis.

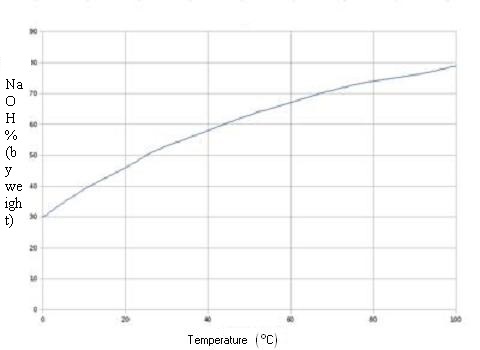

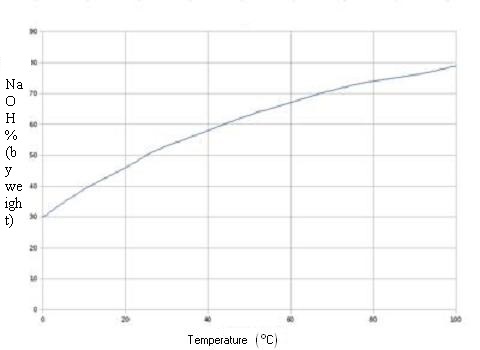

In treatment of water, injection is used in water diluted solid

product (with softened water) or commercial solutions (30 and 50%

NaOH by weight).

Main Features :

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

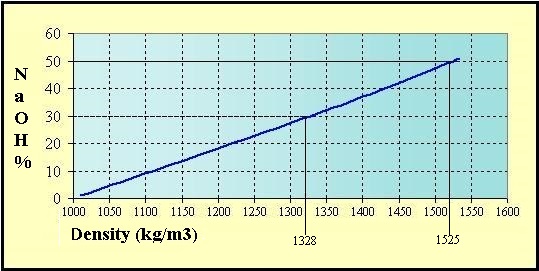

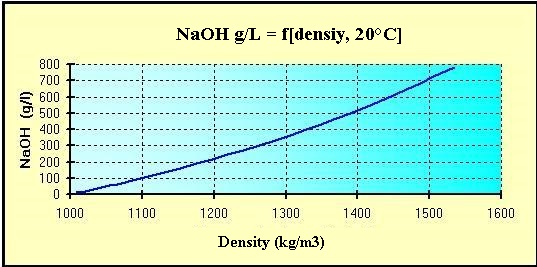

Quantity of pure sodium hydroxide by the Volumetric mass

density [d] of the solutions at 20 °C:

(d = kg/m3 ou g/L)

A formulation for water

treatment.

Reaction mechanism of lime with aggressive CO2 (simplified

equations):

CO2 + NaOH >>> NaHCO3

.44

.........40

...........84 or 50 mg/L as CaCO3

(5°F<TAC)

To neutralize 1 mg of CO2, it is necessary to use

(40/44)= 0.91 mg as NaOH, which

form(84/44)=1.91 mg of sodium bicarbonate NaHCO3, and

therefore also the neutralization of 1 mg /L to form CO2 (5/44) =

0.1136 °F/l de TAC (i.e.1.136 mg CaCO3/L of Alkalinity).

Note: if the calculated dose is a reagent for 100% purity, it is

necessary to correct this dose to entering the purity of the

commercial product.

Standardization.

Standard products used for the production of drinking water:

French

Official Bulletin - Sodium hydroxide, Caustic soda : NF EN

896.

Effects on the environment.

Caustic soda increases the pH of the stream, thus representing a

potential threat to aquatic fauna and flora (stream, river,

groundwater).

Uses.

Sodium hydroxide is a popular strong base used in the industry.

Around 56% of sodium hydroxide produced is used by the industry, 25%

of which is used in paper industry. Sodium hydroxide is also used in

manufacturing of sodium salts and detergents, pH regulation, and

organic synthesis.

It is used in the Bayer process of aluminium production. In bulk it

is most often handled as an aqueous solution, since solutions are

cheaper and easier to handle.

Other:

Safety.

Chemical burns caused by sodium hydroxide solution photographed

44 hours after exposure.

Like other corrosive acids and alkalis, drops of sodium hydroxide

solutions can decompose proteins and lipids in skin, eyes or other

living tissues via amide hydrolysis and ester hydrolysis, which

consequently causes chemical burns and may induce permanent blindness

if it contacts eyes. Solid alkali may also express its corrosive

nature if there is water, so protective equipment such as rubber

gloves, safety clothing and eye protection should always be used when

handling the material or its solutions.

Moreover, dissolution of sodium hydroxide is highly exothermic, and

the resulting heat may cause heat burns or ignite flammables. It also

produces heat when reacted with acids.

The standard first aid measures for alkali spills on the skin is, as

for other corrosives, irrigation with large quantities of water.

Washing is continued for at least ten to fifteen minutes.

Sodium hydroxide is also mildly corrosive to glass, which can cause

damage to glazing or freezing of ground glass joints. Careful storage

is needed.

Sources : personal and Wikipedia,

the free encyclopedia.

(use browser)

(use browser)